China Zhongwang Holdings Limited (the "Company"), together with its subsidiaries (the "Group"), is the second largest industrial aluminium extrusion product developer and manufacturer in the world and the largest in Asia. On 8 May 2009, the Company (stock code: 01333) was successfully listed on the Main Board of the Stock Exchange of Hong Kong Limited. The Group has been primarily focusing on the light-weight development in the transportation, machinery and equipment and electric power engineering sectors through the provision of quality processed aluminium products. The Group has won numerous global certifications and accreditations from the railway, automotive. Shipbuilding, aerospace and other industries. Our customers can be found in major markets all over the world.

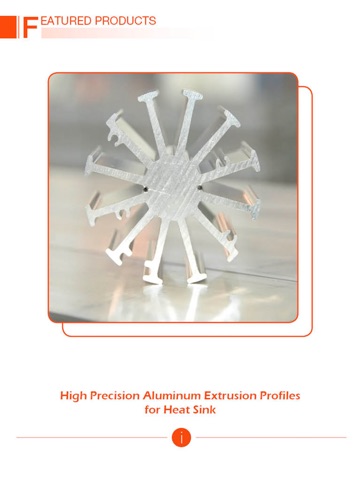

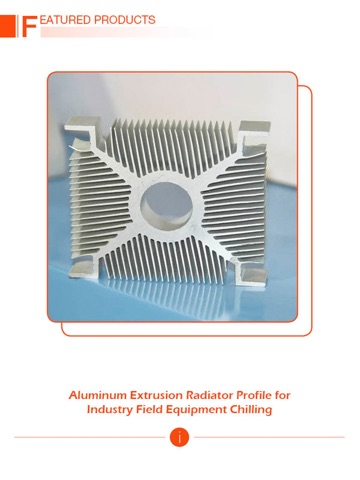

The Group was founded in 1993 with its headquarters based in Liaoning Province, China. After more than 20 years of dedicated development, the Group currently has over 90 internationally advanced aluminium extrusion production lines with an aggregate annual production capacity of over 1.2 million tonnes. In addition, the Group has ordered two ultra-large 225MN extrusion presses, which are the largest and most advanced presses in the world, to be gradually put into operation in 2015. The acquisitions will reinforce the Groups leading edge in the production of high precision, complex large-section industrial aluminium extrusion products. Meanwhile, we have also built a world-leading aluminium tilt smelting and casting facility which is closely linked with the industry chain, as well as the largest customized industrial aluminium extrusion product die design and manufacturing centre in Asia. In 2012, the Group was certified by the Chinese government as a "State Accredited Enterprise Technology Centre". The Groups unique core competitiveness in the industry lies in the comprehensive strength of our four-in-one model, i.e. the integration of smelting and casting, die design, advanced equipment and research and development capability all under one roof. Moreover, our newly built deep-processing centre passed the building safety inspection of the relevant government authorities in June 2013 and duly commenced production. This development will enhance our production capacity in deep-processed products and lay a solid foundation for the extension of our business scope to high gross margin business of downstream products.

The Groups high value-added aluminium flat rolled product project is progressing steadily as planned. At present, the equipment purchase and land acquisition plans for the preliminary phase of the project have been accomplished and we have now started the tender process for different stages of construction successively. Phase I of the project with a designed annual production capacity of 1.8 million tonnes is expected to gradually commence production in 2016, by which time we will have initially achieved the goal of tapping the high-end aluminium flat rolled product sector to become our third core business complementary to and synergistic with the existing industrial aluminium extrusion product and deep-processed product businesses. The Company expects the investment for phrase II of the project to be completed by 2018, by which time the total designed annual production capacity of 3 million tonnes will have been realized.

The Group will continue to focus on light-weight development in the transportation, machinery and equipment and electric power engineering sectors that aims at reducing energy consumption and facilitating low carbon emission. It will actively seek to sharpen its edge in the industrial aluminium extrusion sector, extend its reach to the high-end aluminium flat rolled product business and develop aluminium deep-processing technologies, working relentlessly to become the worlds top comprehensive developer and manufacturer of high-end aluminium products.